To berth and unberth large ships, it is necessary to have the assistance

of high-powered tugboats to maneuver them with ease. Also, they are

amazing players when some emergency assistance is required on

ports. These port tugboats are the strong guys of the ports and are

characterized by their Bollard Pull capability.

Bollard Pull: It is the measure of the traction in a cable, generated by the tug when it is at maximum power in its engines when connected to the tug’s winch or towing hook, a load cell, and a large, sturdy bollard on a pier. Its unit of measurement is usually in tons (t).

In other words, the vessel exerts its maximum force while being stationary, connected to the pier by a cable, like in a tug-of-war.

The Brazilian rule NORMAM02-ANEXO3-I specifies all the necessary conditions for conducting a static traction test. As well, classification societies have their specs for the Bollard Pull trial.

Modeling a Bollard Pull estimator

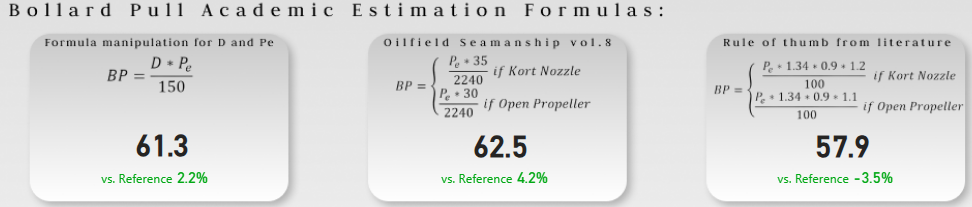

There are some Bollard Pull estimation formulas in the literature, and many of them use only Break Horse Power BHP as the variable to determine BP. But it is known that BP is a result of BHP, Propeller geometry, and other tug characteristics.

See bellow examples, given:

Comparison tugboat BP=60t

D=2.3m

Pe=4000kW

no kort nozzle

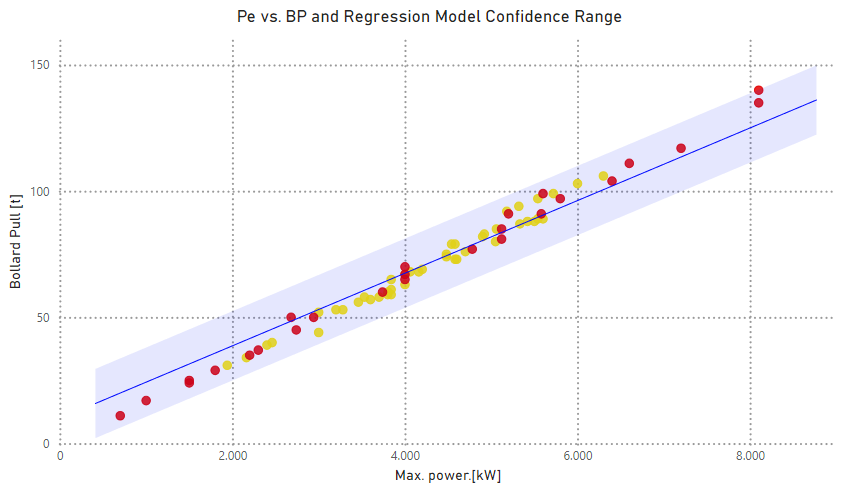

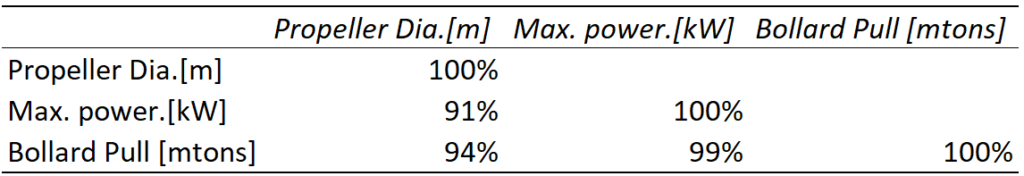

Researching some specifications, and results of bollard pulls, I decided to use some simple data modeling and analytics to develop this article to propose an equation to determine the Bollard Pull of tug boats in the function of its propulsion diameter and total power of the engines.

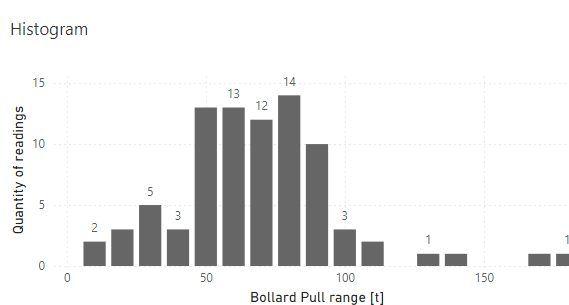

The data collected to develop the study and the regression were found from Kongsberg and Caterpillar catalog of products, generating a total 84 observations.

After evaluating the values and performing data analysis with MS. Excel, it was noticed that values of diameter and max. Power provide a high correlation with Bollard Pull. Diameter and Power to Bollard Pull, 94% and 99% respectively.

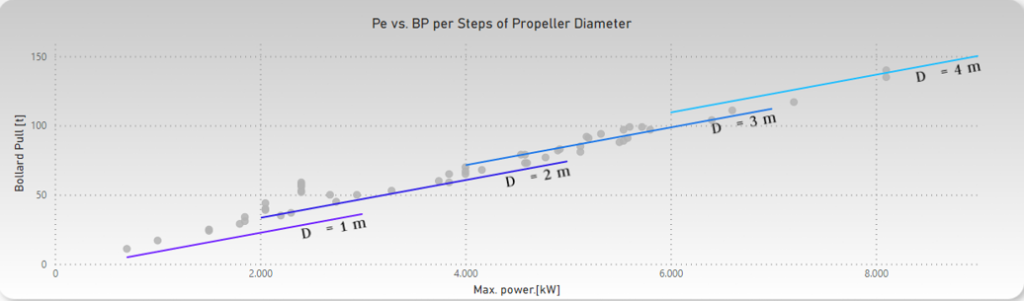

;As the chart shows, the outcome of the linear regression aligns with the values within the database range for propeller diameters between 1 and 4 meters.

Given that Total Power for harbor tugs usually does not exceed 8000 kW, this equation could provide an exciting outlook for the initial design stage.

Nevertheless, it is possible to observe that as the Total Power grows, the results of Bollard Pull are more accurate as the diameter is raised.

In real design, It is expected to happen, due to high-power equipment will not use a small propeller as well a low power will not use a big propeller.

This can be associated with the fact of propeller geometry, performance, and cavitation issues which need to be considered when developing a new tug design.

With this view, it may be an interesting option to segment the BP result between Total Power values accordingly to propeller diameters, as it is shown below, where the BP was segmented for D= 1 , 2, 3 and 4 meters, between a range of total Power.