With all its size and quantity of steel, do you imagine that the ship still suffers great mechanical stresses that make it flex and even collapse?

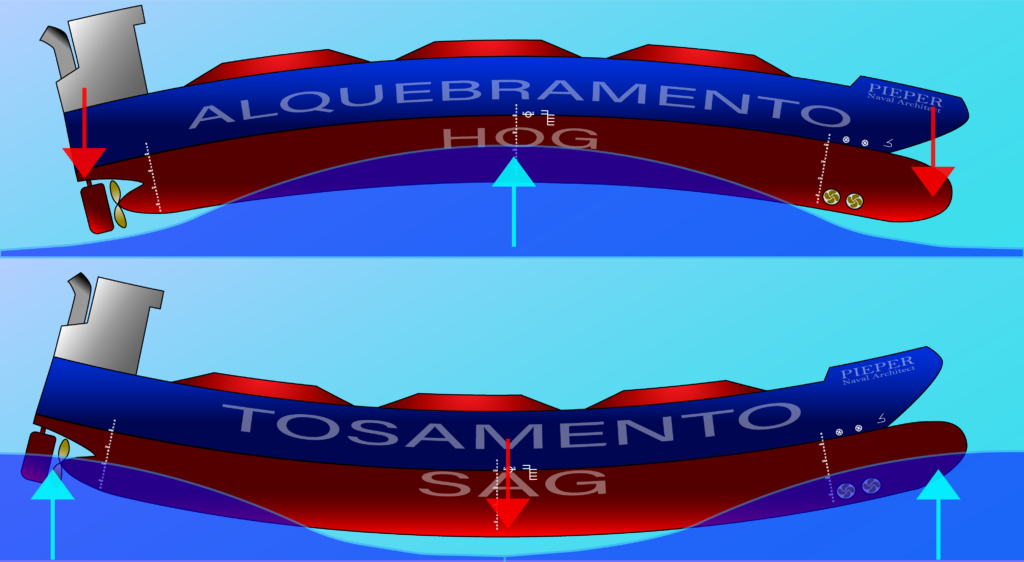

Well, there are two main occurrences in which the ship is taken to great mechanical demands, high stresses and that need to be evaluated in the project. Hog and Sag! Let’s consider a wave similar in length to the ship.

✔HOG: The ship is on the crest of the wave, in this case, the buoyancy is concentrated in the center of the ship and causes the bow and the stern, by gravity, to force the hull to be in the shape of an “n”

✔SAG: The ship is in the valley of the wave. Here the buoyancy will be concentrated at the stern and the bow, the middle of the ship is forced downwards, making the hull be in a “u” shape.

When going through these situations, depending on how the load is allocated, the effects can be greater, so the allocation and planning of loads in the most distributed way possible are important.

Concentrating the load at specific points along the hull can not only impact its energy efficiency but its structure as well.

In the next post, I will talk more specifically about the structural part!